Pieter has shared his plans for Sasha, the repeating crossbow!

Crafting the Essence of Death and Nature: Pieter’s LARP Druid Staff Project

Today, we embark on yet another exciting project journey from Pieter of Arcana that started with a familiar question: “Could you make something new for me?” And as always, the enthusiastic response was, “Sure, if you can describe what you would like, it will spark an idea.”

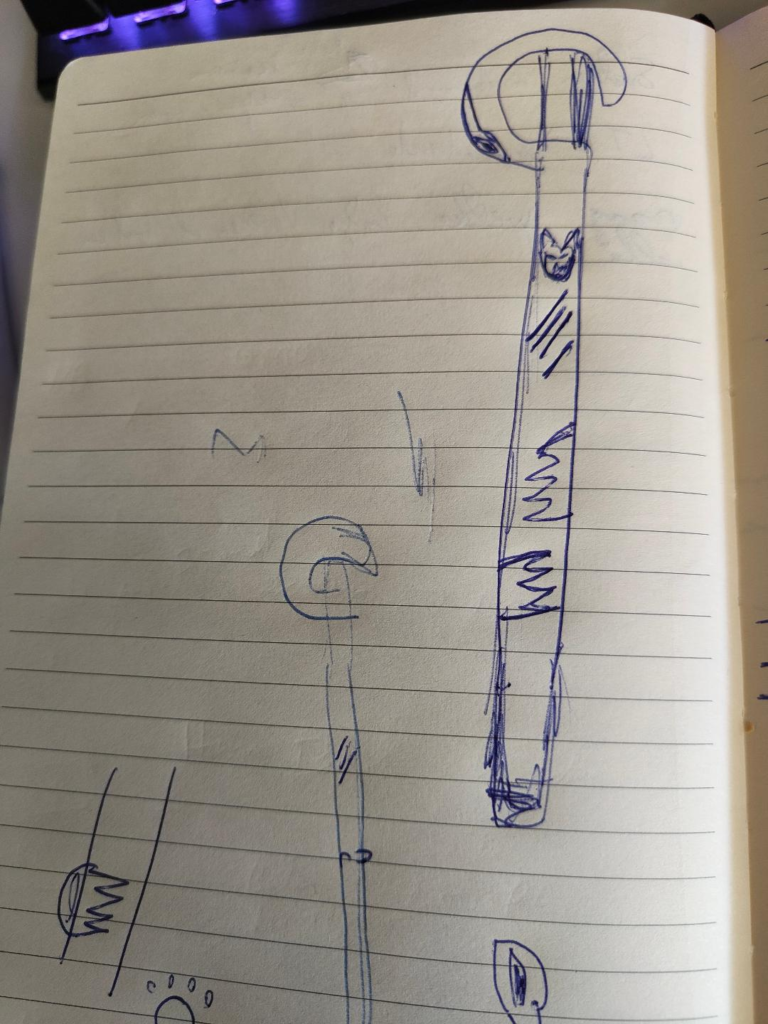

So here we are, with a raw sketch and a brief in hand, ready to jump into the creation of a unique LARP Druid Staff. The brainchild of the talented Pieter, this staff is envisioned to embody the essence of the All Father, encapsulating themes of death, decay, and autumn. Picture a dark, mysterious staff that, despite its ominous aura, maintains a distinctive connection to the natural world.

The foundation of this project lies in a sketch—a rough representation of the idea’s potential. Remember, in the world of creativity, it’s the idea that counts. Alongside the sketch, there’s a brief description guiding the design process.

The vision is clear from the sketch, a staff that is both dark and recognizably wooden. The challenge? To infuse the staff with the essence of the All Father, creating an object that breathes the very spirit of death and decay. Adding an element of the Were Bear introduces an intriguing twist. Claw marks adorn the sketch, leaving a mysterious tale in their wake.

The aim is to maintain a height of 180 cm for the staff, ensuring a commanding presence on the LARP battlefield. Imagine wielding this mystical creation, a tangible connection to the forces of nature and the mysteries of the All Father.

To enhance the mystique, Pieter envisions the staff featuring a recognizable sickle—a symbol of harvest, death, and the cyclical nature of life. To push the boundaries further, he contemplates the inclusion of subtle traces of blood, adding an element of grim reality to the fantastical design.

New guide for making glowing lightsaber blades!

It’s a little different than the heavy boffer focus we normally have here at foamsmithing.com, but this should be of interest to anyone seeking a Star Wars game or cosplay. Also suitable for magical glowing blades for fantasy, steampunk, and other settings!

New page on Stab Tips now up!

Today we posted a guide on creating Stab Tips! You can also find it through the menu at the top of each page.

The guide details how to use Yoga Mat foam to create a stab tip for flat bladed boffer weapons. This method results in durable, safe, and attractive stab tips, with minimal material and labor costs. Go check it out!

Latex/EL Wicked Axe by Pieter

Making plans

A friend of mine asked me if I could help him with an axe he wanted to build.

Dimensions: 110 cm (3 feet 7 inch) and double bladed.

The Inspiration

Construction

A rough design:

In the drawing you can see that the internals are drawn as well. It is better to plan ahead!

Making the parts. Knowing what goes on beforehand is a tricky part and varied from weapon to weapon, but pretend it’s real and imagine yourself a blacksmith.

The frame is made-up clued together kite spare covered in cloth.

The cloth is glued and stitched. Glued together and cut to size. Note the barbs where left out because it was felt that it would weaken the weapon. The handle is made from wood and crafted so it will take two AAA batteries. The switch is placed at the backend of the weapon and foam protected.

After some more gluing and latex-ing:

Note: 6 layers of clear latex 3 colored (black)

Than the red, and metallic are directly airbrushed on to the latex.

Covered with a coat of plastidip clear and finished with a light coat of clear varnish.

And here it is with the lights on:

Wear and Tear: Swords

We play a rough and tumble game, so no boffer weapon can stay pristine forever. Knowing how to repair a weapon is a useful talent, which will prolong the life of your equipment and keep your wallet happy. Lets run down some common problems you’ll see, and how to repair them. Continue reading “Wear and Tear: Swords”

New page up on Fiberglass Cores

Solid fiberglass rods are the go-to core technology for boffer swords. They are affordable, easy to use, and durable. We heartily recommend them, and detail their usage in our latest component guide.

Hi-Tech Sword Building for New People

Solusar of Belegarth has a great gallery/tutorial on his blue sword build, with good details like tip-foam teeth, a tip-biscuit, and a non-mushroom-cap stabbing tip. Lots of interesting commentary. We recommend it highly: Solusar’s Hi-Tech Sword Building for New People

How to make Hilt Guards-Two Basic Guides Posted!

A basic guard can turn a good sword into a masterpiece. There are two (similar) methods we use to make guards. You can embellish the basic process to create tsubas, crossguards, or even a basket hilt (with the Stack Method). Both methods are durable and easy to construct. The Box Sandwich method is slightly less reliable (less foam contact with the core) and can only be used with 1/2″ fiberglass.

Two more tutorials online

We’ve put up two more tutorials this week:

Both are basic skills that every foamsmith should know. You can find them through the component menu item, or through specific weapons guides. For example, the article on pommels is linked in the guide for blue swords, red swords, and spears.

Expect more articles up before this week is out.